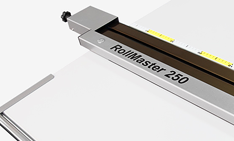

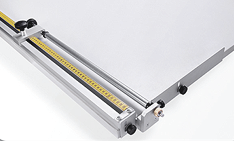

On the front part of the table there is a holding bar which

presses the material. Default is a manual mechanism operated by hand, which can

be optionally expanded to pneumatic version.

In the basic version it is operated manually using a handle.

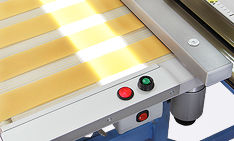

In the pneumatic version, the holding bar lifts with a push of a button, and lowers with its release. This version also includes an option of lifting the holding bar shortly by pressing an additional foot button. This option is helpful in a situation when the unfolded fabric is not situated at the right angle.

The pneumatic version allows lifting the holding bar higher (over 1 cm). It is recommended when working with thicker fabrics, as well as day-night type of roller blinds.

This part must be selected while ordering the cutting table.

This part must be selected while ordering the cutting table.

More photos

More photos

Watch video

Watch video